We provide pedestal and chuck heaters to the semiconductor industry. Our solution is used in vacuum deposition processes in wafer production.

A reputation for innovation

THERMOCOAX has an industry-wide reputation for designing and engineering highly innovative products which exactly meet the needs of customer specifications. Although pedestal and chuck heaters may at first sight seem simple, the design parameters are extremely complex, and require a great deal of consideration and development.

Every stage of prototyping and manufacture, testing and control, is undertaken in-house, working in close collaboration with our customers.

We provide heating solutions for OEM machine builders for thermal ALD, PVD, and CVD semiconductor processes.

Custom made, every time

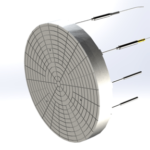

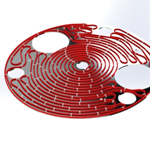

Each new design concept is bespoke to a customer application. Excellent heat conductivity, temperature homogeneity, and guaranteed surface flatness are all essential qualities, with customisation including thermocouples, gas lines, cooling line, texturing, and specific coating options.

Pedestal and chuck heaters meet industry needs

Pedestal and chuck heaters are made from a variety of customer-defined materials, including :

- Stainless Steel

- C22

- Aluminium

- Nickel

- Specific Inconel Alloy

Sizes are typically up to 300mm diameter, but can be greater than this, depending on proposed use. Multi-heating zones provide high uniformity of temperature – depending on operating conditions – and all products are Ultra High Vacuum compatible.

THERMOCOAX offers full encapsulated metal heating plates to avoid any contamination in the deposition chamber.

Choose the high-end solution

Every project starts with a specific problem: a high-tech application where the customer has found no existing product to meet issues such as energy density distribution, heat uniformity, material deformation, welding or brazing.

Semiconductor manufacturers need high-end solutions which are at the same time designed-to-cost. THERMOCOAX products meet and exceed existing equipment specifications, with shorter lead times, improved reliability, and reduced maintenance. Parts replacement, when needed, is swift and easy.

Our chucks and pedestal heaters generate a uniform temperature up to 900°C. Internal test procedures, during production, warranty temperature homogeneity on multi heating zone heaters.

Resistance to chemical cleaning during process deposition and etching is ensured by construction in a range of metals defined by the customer, in consultation with the THERMOCOAX design team.

Our unique approach

The design and development of every custom-created product is part of the unique approach we bring to the market. Each new project has a dedicated Manager, engineering, and quality control teams, who work directly with customers to develop exact solutions for their specific design needs.

We are also familiar with More than Moore applications, working at the highest of high-end products and performance.

The result? Custom heating chucks and pedestals that meet the exacting needs of customers worldwide, with a highly cooperative design and development process which is designed-to-cost, while meeting – and exceeding – industry expectations.

Pedestal and chuck heaters : technical data

For more detailed specifications and information about our pedestal and chuck heaters, please do not hesitate to request a quote.