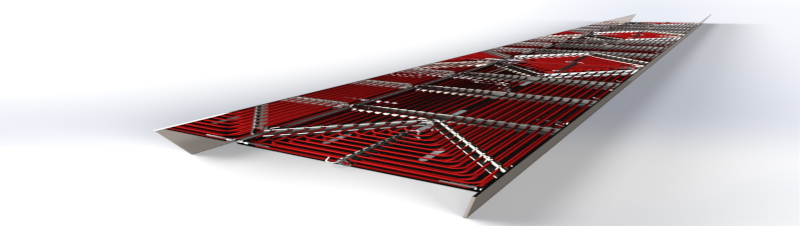

THERMOCOAX has a range of customised thermal solutions, including Radiative Heating Plates made to the exact shape and dimensions specified by customers.

Working across all applications

THERMOCOAX has a wide range of customised thermal solutions for vacuum deposition processes in semiconductor, photovoltaic cells, display, touch panel, Organic Light Emitting Diode(OLED) manufacturing processes, up to 900°C.

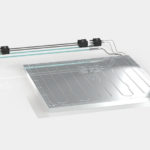

This includes Radiative Heating Plates made to the exact shape and dimensions specified by customers. Suitable for use in air, plasma, high pressure, high frequency and ultra-high vacuum environments, our Radiative Heating Plates are typically manufactured from :

- Stainless steel

- Aluminium

- Other specified alloy

Meet technical requirements with our heating cables

Heating cables are designed to meet client requirements, e.g. in terms of sheath/geometry/length. Small diameter heater/bending radii also allow matching to any shape or profile. And cold end mineral insulated cable heaters come in single core or dual core designs.

Complete capability

THERMOCOAX has the capability – including brazing, TIG welding, laser welding, cable production, and assembly – to manufacture the complete application, with heaters plus sensors brazed directly onto parts.

Our manufacturing process is 100% controlled, with a commitment to traceability of processes throughout the whole product chain. We also carry out subcontractor assessment, and full internal and external audits for complete regulatory compliance.

We also dedicate a special Project Management team to all large production programs to ensure delivery of the specified product.

Radiative Heating Plates features

Radiative Heating Plates from THERMOCOAX bring a number of essential features and benefits :

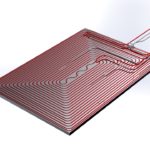

- True cold end heaters mean that there are no internal connections, so that cables respond perfectly to the needs of the final piece in terms of power density per heating zone.

- Thermal stability and temperature control thanks to our Thermocouples that enables fast response-times, allowing accurate measurement of very short temperature variations, ensuring excellent process monitoring.

- Connectors for Radiative Heating Plates can be specifically manufactured for applications, covering working temperatures from cryogenic to 900°C and above.

As a result, accuracy, stability, and reliability are guaranteed through precise control procedures, to meet the demanding specifications of many industries which utilise vacuum applications.

Welcoming new challenges

What sets THERMOCOAX apart as a designer and manufacturer of Radiative Heating Plates for PVD Processes and other associated uses is the cooperative approach taken on all projects. We always bring our experience and deep knowledge to new designs and applications, but are also fully committed to working with our customers to create the very best solutions for specific needs.

We know that delivering cost-effectively is vitally important for every customer. However we never compromise on quality, and deliver custom designed shaped and sized products to exactly meet specifications, at the right price.

As with all THERMOCOAX solutions, we take pride in the excellence of our Radiative Heating Plates, and constantly welcome the new challenges set by our industry-leading customers.

Radiative heating plates : Technical data

For more detailed specifications and information about our radiative heating plates, please do not hesitate to request a quote.