THERMOCOAX designs and supplies 3D Full Assembly Heating Solutions, from prototyping through to high-volume manufacturing.

Higher Yields and Less Downtime

Customers increasingly need higher yields in the wafer manufacturing processes, with improved specifications and reduced maintenance or downtime. Complex machined or additive manufacturing 3D heating solutions require :

- high performance heating cables

- perfect mastery of welding and brazing technologies

- behaviour knowledge of the various materials during these processes

- temperature control solutions which go far beyond conventional plate heaters, and are fully integrated into systems operating at up to 900°C.

Stability with the highest precision

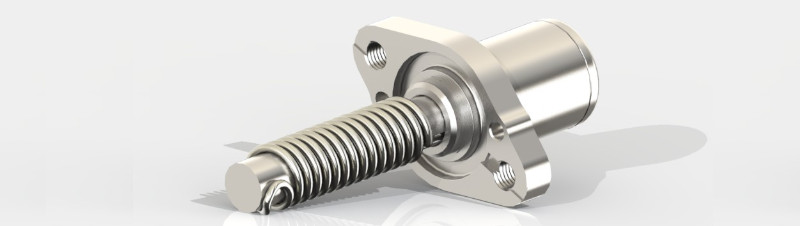

THERMOCOAX leads in the design of Full Assembly electrical thermal solutions. This includes mechanical parts, machining, additive manufacturing, welding and brazing, and shaping and fixing custom designed heating cables and temperature probes.

In high precision full assembly heaters for wafer manufacturing processes, exact and evenly distributed temperature control is essential. This includes applications such as :

- Epitaxy

- PACDV

- PVD

- Lithography

- Gas Injection Systems (GIS)

- UHV Pulverisation

- Evaporation

Our core offering is based on the design and production of Mineral Insulated cables , including all mechanical parts. In-depth experience is brought to the area of Full Assembly Heating, where – for example – cylinders will reach temperatures from 450°C to 900°C .

Our products ensure control of energy distribution, and temperature homogeneity over the manufacturing process of our OEM customers.

100% controlled

THERMOCOAX Full Assembly heating products are manufactured in our factories in France and in the US, where we design custom heaters and temperature sensors to meet the specific demands of a wide variety of industries.

Our heating systems can be incorporated in many applications, including Ultra High Vacuum, and other diverse severe environments, where complex 3D thermal solution designs are needed.

Every production process is 100% controlled, which means that every product is 100% controlled, and we offer full traceability of all components and sourcing. This includes regular audits of our suppliers, and of our own production sites by customers and external organisations.

Custom designed and built

All THERMOCOAX 3D Full Assembly heating solutions feature Mineral Insulated cables manufactured with true cold end, meaning no internal connections. Our mineral insulated heating cables are available in small diameters, with small bending radii, allowing compact heating solutions and perfect control of the heating distribution on parts with complex design, up to 900°C. This enables the specified needs of power density per heating zone.

We also manufacture specific connectors, working closely with customer engineering departments to optimise designs.

Cold end Mineral Insulated cables can be single core or dual core. Cables can be manufactured specifically to respond to customer specifications in sheath/geometry/length ratios, which allow matching to any shape or temperature profile.

We also have accreditation from the internationally recognised COFRAQ, which certifies our temperature sensors calibration laboratory.

The one stop shop

3D Full Assembly Heating Solutions are used in complex production system, such as severe thermal, UHV, and other challenging environments. We are experts in thermal engineering, mechanical design, brazing and welding, control and testing.

3D Full Assembly Heating Solutions : Technical Data

For more detailed specifications and information about our 3D Full Assembly Heating Solutions, please do not hesitate to request a quote.